Liquid X® Textile-based Force Sensors (FSRs)

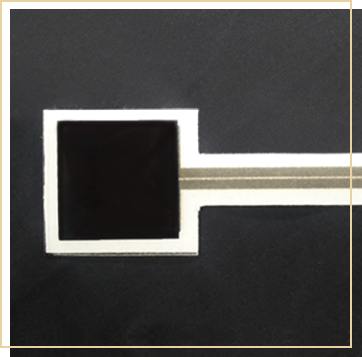

Liquid X shunt mode FSR on nonwoven fabric

Liquid X custom designs and manufactures textile-based FSRs by printing its particle-free metallic ink directly on the textile substrate. Typically, FSRs are printed on multiple layers of sheet form PET (silver interdigitated fingers and then carbon layer). For textile applications, these layers of PET would be laminated together, then laminated onto the fabric requiring discrete wiring for connection to hardware.

With Liquid X’s textile-based FSRs, the particle-free metallic ink is deposited directly on the textile, enabling FSRs printed directly on the fabric. A printed carbon layer on flexible plastic is then laminated directly over the interdigitated fingers. Liquid X’s silver traces can be utilized as the circuit as well, eliminating the discrete wiring and reducing materials and steps in the manufacturing process while enabling durable force sensing technology directly on textiles.

Standard and Custom Solutions for Embedded Sensors

Off-the-Shelf Solutions

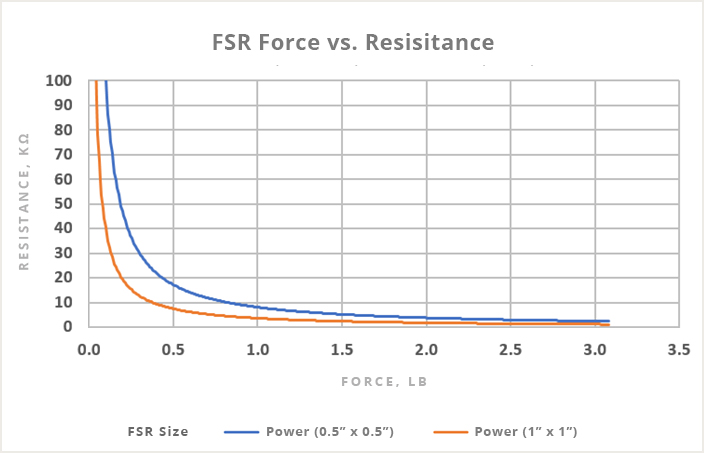

Liquid X® currently offers textile-based force sensors in two standard sizes, both with a 2″ tail:

- 1” x 1” sensing area

- ½” x ½” sensing area

Available connection methods include:

- Male solder tabs

- Female connectors with plastic housing

Customizable Solutions

Liquid X® partners with companies to develop tailored FSR solutions based on specific applications needs. Options include sizing variations of the sensing element along with sensitivity adjustments to alter the response curve.

We can print the sensor base layer directly on your fabric in the size and shape that meets your exact requirements. Contact us to learn how force sensors can be integrated into your application.