Liquid X® E-Textiles

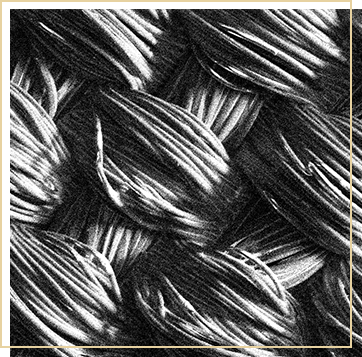

SEM Imaging of Liquid X’s particle-free

ink on woven polyester fabric

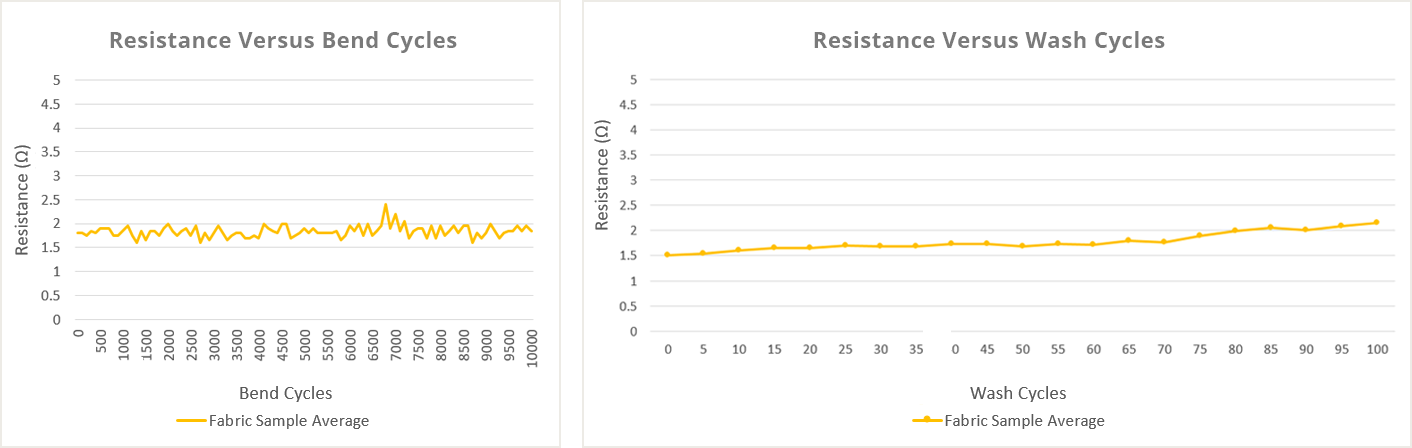

Liquid X is utilizing its proprietary, particle-free ink as the enabling technology for the development of electronically integrated textile (e-textile) devices.

Through additive manufacturing techniques, Liquid X’s particle-free ink is deposited directly onto the fabric, conformally coating the fibers of the fabric to create highly conductive traces, enabling cost-effective, durable solutions for textile-based products while maintaining the integrity of the base fabric material.

Product Advantages

Process Advantages

Current Applications

- Health & Wellness Monitoring

- Biosensing (EKG, EMG, temperature, etc.)

- User Comfort

- Resistive heating elements

- Fashion

- Color changing technology

- LED circuitry

- Defense

- EMI Shielding

- Connected Soldier

- Tracking

- Passive RFID

- Energy Harvesting & Storage

- Triboelectric Nanogenerators (TENG)

- Printed batteries

- Wireless charging

- Command Controls

- Capacitive touch

- Proximity

- Force Sensitive Resistors (FSR)

- Connectivity

- Surface mount components for hardware connection

- Printed flexible circuits

- Connecting multiple products to create an integrated system without using wires

- Bluetooth connectivity for connection to other devices

Scholarly Publications

Kirigami‐Inspired Textile Electronics: K.I.T.E.

Find out more ►

Inkjet Process for Conductive Patterning on Textiles: Maintaining Inherent Stretchability and Breathability in Knit Structures

Find out more ►

Inkjet Printing of Reactive Silver Ink on Textiles

Find out more ►

Tailored solutions for any industry

Liquid X® products are custom engineered and tested to perform in nearly any application. Learn how we can facilitate the use of our functional electronic products in your application, create a prototype, and get it to market faster.